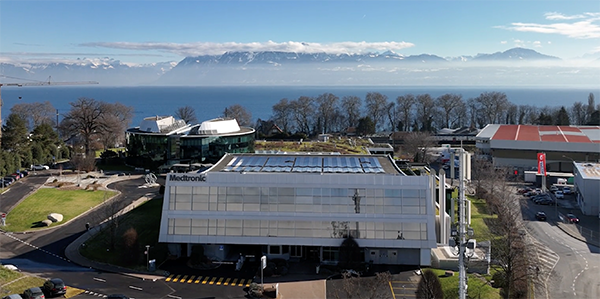

How Lake Geneva helps heat and cool a European manufacturing site

Hydrothermal renewable energy project reduces CO2 emissions by 80%, contributing to sustainable energy future at Medtronic

As the Medtronic Switzerland campus expanded in 2001 and again in 2009, its oil-fired heating and cooling equipment became obsolete and needed replacement.

François Monory, who led manufacturing at the site, saw this as the ideal opportunity to introduce a unique renewable energy concept he learned about years earlier: using water from nearby Lake Geneva to help heat and cool the buildings.

The hydrothermal energy project — dubbed ENERLAC — would pull water from the lake through underground pipes to a nearby site where heat pumps could convert energy from the water temperature to warm or cool the air in buildings across the campus. The water would then be returned to the lake with no impact to the local ecosystem while simultaneously reducing CO2 emissions.

The science behind the concept was simple, but planning and executing the complex initiative would take more than 14 years. Watch this video to learn more about how it happened.

“We studied this project with one ambition, that the cost of this investment must not exceed the cost of using fossil fuels over the next few years,” said Monory. “I underestimated the complexity of dealing with various state entities. Fortunately, I was surrounded by some talented people who helped make this very cool idea a reality.”

A small team at Medtronic worked with local contractors and government agencies to come up with a plan that everyone could agree on. In the Summer of 2020, during the global pandemic, crews began the three-year process of bringing ENERLAC to life without disrupting operations at the Medtronic facility.

By eliminating dependence on fossil fuels, ENERLAC reduced and stabilized energy costs at the site for the next 30 years while also drastically decreasing CO2 emissions by more than 80% — from 820 tons per year to approximately 150 tons per year. The project is an important step in helping Medtronic reach carbon neutrality in its operations by FY30 and achieving a net zero emissions target across the business by FY45.

In Tolochenaz, community leaders praised Medtronic and heralded the innovative project as an important part of the area’s ecological transition.

“Today with hindsight we can say this project was the right thing to do, but 10 years ago there weren’t many people who thought like that,” said Dr. Stéphane Genoud, Head of Energy Management at HES-SO Valais-Wallis University in Switzerland. “To have a company that decides over ten years to carry out a project like this means they really have a long term vision, and that’s quite original.“

L00107242023

Related content